Mao Yuhai: Nephew of Mao Yisheng who is famous and outstanding bridge expert, associate professor at Electrical Engineering Collage in Cornell University, professor at Electronic Engineering department in Tsinghua University.

-

Since 2013, Mr. Mao developed the "LED-Engine" and patented. Meanwhile, he combines several companies including Tsinghua Tongfang to develop "LED-Engine" series. "LED-Engine" quickly swept the whole market! The main reasons are the cheapest cost, the simplest production process.

-

But now, Mr. Mao warns us "LED driverless is meaningless" and . Somebody says "LED driverless and LED-Engine are the trend of future". We have to clarify because it will mislead LED driver and LED products industry.

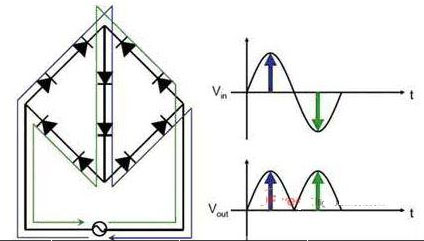

LED Driverless:

As the input is AC, it's like rectifier and four pieces of LED forms so-called AC-LED. Taking an example of 2835(1734 Wafer), Naked LED is 120lm/w(150mA Drive)~180lm/w(60mA Drive) but we could only set 150mA at wave peak. Otherwise, LED must be burnt in some day. Then, it losses many light efficiency(around 15%) for AC wave and we spend double cost of the LED. That's why the concept is meanless.

-

LED Engine:

CREE already make a test of the life comparing separate driver and LED Engine will shorten at least 3 times of the life span. What's the reason? LED Engine means driver components was SMT with LED together. Up to now, the engine efficiency is around 75%~85%. As the components power heat could not be released first step to the heat-sink because of the PCB isolated layer, LED has to absorb the heat firstly. Now, LED efficiency is 40%, in another words, 10W LED has 6W heat. The driver components has around 1.5~2W to be absorbed by LED(25%-33% temperature rise directly). With 10℃ rise, LED life will shorten 2 times. Mr. Mao also said this technology is mainly for some poor countries. If thinking of life solution, LED Engine efficiency has to be the highest like 95%-99%, which need to be striven for continuously.

-